chain ක් රියා කරන ආකාරය තේරුම් ගැනීමෙන් ඔබට එහි ප් රයෝජනවත් බව වඩාත් හොඳින් දැකීමට ඉඩ සලසයි...">

'රැක් සහ පිනියන්' මැකනිසම් එක් සරල නමුත් මෙහෙයුම් ප්රතිඵලයක් ලබා දෙන බැවින් වෙනත් මැකනිසම් වල භාවිතා කරන්නේ වෙනත් මැකනිසම් වල භාවිතා කරන්නේ කේන්ද්රය ක්රියාත්මක කිරීම් ඔබට ඔබගේ අපූරක වල එය භාවිතා කිරීමේ යුග්යතාව දැනගැනීමට හැක. මෙහි, අපි අඩු රැක් සහ පිනියන් විසින් ලැබෙන ආදායම්, ඔවුන්ගේ අපූරක වල භාවිතා, ඔබගේ ප්රජ්නාවන්ට සුදුසු එකක් තෝරාගැනීමට යොදාගැනීමේ පරිමාණ සහ මාරු කිරීමේ ඉඟි.

අඩු රැක් සහ පිනියන් පද්ධතියේ මූලික දෙකක් පැති වේ. රැක් යනු එක් පාර්ශවයෙන් පැදැල්ලුවක් වන අතර, පිනියන් යනු රැක් සහිත පැදැල්ලුවකට සම්බන්ධ වන තරම්පත් චක්රයක් වේ. මෙම පිනියන් රැක් සරලව ගෙන්නට පත් කිරීමට යොදාගැනීමට යොදාගැනීමට යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන් යොදාගැනීමෙන්.

මුලික ලාභයක් වන්නේ conveyor line සැකසුම එය සරලව පැහැදෙන්නේ. මූලික කොටස් දෙකක් පමණක් ඇති අතර, එය භාවිතා කිරීමට හා පුළුල්කරණයට යැස් ය. එක් වශයෙන්, රැක් සහ පිනියන් පද්ධති නියමිතාවය ලබා දෙයි, එබැවින් ඔවුන්ට අවසානයේ යොමු කිරීමට ප්රේක්ෂිතව එක් වශයෙන් වස්තූන් වෙන්වීමට හැකිය. රැක් සහ පිනියන් පද්ධති අඩු වශයෙන් බලපෑම් ලබා දෙයි, එබැවින් බලවත් ක්රියාකාරකම්ට සුදුසු වේ.

අනෙකුත් ස්ථානවල රැක් සහ පිනියන් පද්ධති අඩු වශයෙන් ඇත. උදාහරණයක් ලෙස, දුක්ට් යානත් මැළින් රින්තුවාලියේදී තURREL යාන චලිතය උගැන්වීමට භාවිතා කරන්නේ. ඔවුන්ට මැළින්, රෝබෝට්, හා අනෙකුත් ප්රේක්ෂිතව ඔ්යාන් තුළදී ද ඇත. ඉංජිනේරුවන් සහ භාණ්ඩ සාමාන්යයෙන්ම රැක් සහ පිනියන් පද්ධති භාවිතා කරන්නේ ඔවුන්ට අනෙකුත් වශයෙන් ක්රියාකාරකම් කිරීමට හැකිය.

ඔ ඔබට ප්රජේක්ටය සඳහා කුඩා රැක් සහ පිනියන් තෝරාගත් විට අමතර ප්රමාණ ඇත. ප්රථමයෙන්, ඔබට යොමු කිරීමට දැන්වෙන මූලික දේවනියක් වන්නේ ඔබට යොමු කිරීමට අදාල අයිතම් කුමක් වැදුවා හා බරපත් ය.

ඔබේ කුඩා රැක් සහ පිනියන් සුළු පැවසීමට නියමිත රූපාවකාශනය අත්යාවශ්යයි. එය ප්රධාන ක්රියාවලින් පිළිබඳව පැවැත්වෙන්නේ එය සුළු ගැනීම, ගෙයින්ට තෙල ආවේශනය කිරීම සහ විනාශයන් සඳහා අවලෝකනය කිරීමයි. ඔබට මූලික දේවනියක් දැක්වෙන්නේ මූලික දේවනියක් වැදුවා හා බරපත් ය.

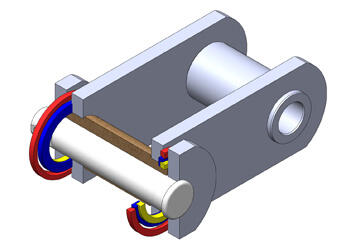

විවිධ නිෂ්පාදන ප්රතිඵල ප්රමාණය: විවිධ අනුපාතවල අත්යාවශ්ය නිෂ්පාදන චේන් කොන්වෙයිර් සිම්, PTO ශාෆ්ස්, ස්ප්රෝකට්ස්, ගීර්ස්, කූප්ලින්ග්ස්, V-පූල්ස්, සහ වෝර්ම් ගීර් රිඩියුසර් වැනි අනෙකුත් අනුපාතවල අත්යාවශ්ය නිෂ්පාදනය අඩංගු කරමින් මෙම නිෂ්පාදන ප්රතිඵල සින්දු සිගෘහය සහ ජලය සහිත ඉංඩුස්ට්රියෙහි අත්යාවශ්ය යුද්ධ ප්රතිඵල ප්රමාණය පැවැත්වෙයි. මෙම නිෂ්පාදන ප්රතිඵල ප්රමාණය භාවිතා කිරීමෙන් භාවිතා කරන අතර මුල් අසාර්ථකත්වය සහ මුල් පාලන අගයන් අඩු කිරීමට උපකාරී වේ.

අධික පාර්ශවය සම්බන්ධ සංස්කාරය: 2005 මීට ස්ථාපනය කරන ලද්දේ, එහි ආකෘති මැඩලුවුන් 2000 දක්වා යොමු කරන ලද්දේ, යාම් බෝක්ස්, චේන්ස්, ත්රාන්ස්මිෂන් ශාෆ්ට්ස් සහ ත්රාන්ස්මිෂන් ලයින් අංශ වැනි වෙනත් ක්ෂේත්රවල නිර්මාණ විශාරදත්වය පිළිගැනීමට පෙර පිළිවෙලක් ඇත. මෙය එය නැවත නැවත නිර්මාණ සහ ගොස් ප්රතිඵලනය සඳහා ප්රබල සාමාජික හැඳින්වීම සහ අදාළ ප්රතිඵලනය ලබා දීමට හැකි කළේ. ප්රාප්තිමත් රැකියාවේ අනුව නිර්මාණය කිරීමට හැකි අතර, ඉංජිනේරුම් අංශ වැනි වෙනත් ගැටුම් අවශ්යතා සඳහා නිර්මාණය කිරීමට හැකියාව ඇත. මාර්කට් ප්රතිඵලනයේදී එය බලේන්නේ ප්රබල විශ්වාසය සහ සාම්යතාවයි. මෙහෙයවීමේ අභිප්රාය මාර්කට් විශ්වාසය: රැකියාවේ අනුව ප්රතිඵලනය කිරීමට අත්සන් පිළිබඳව බලාපොරොත්තුවක්, රැකියාවේ අනුව ප්රතිඵලනය කිරීමට අත්සන් පිළිබඳව බලාපොරොත්තුවක්, සහ බාහිර රැකියාවේ සමඟ දීර්ඝ සම්බන්ධත්වයක් ඇති අතර, එම ප්රදේශයේ මාර්කට් වල ප්රතිඵලනය ප්රචණ්ඩයි. එය යුරෝපියානු මාර්කට් වලදී ප්රචණ්ඩ විය යුතුයි, මුල් රැකියාවේ අනුව ප්රතිඵලනය කිරීමට අත්සන් පිළිබඳව බලාපොරොත්තුවක්.

අධුනාගත නිර්මාණ සහයෝගී සංස්ථාන: නිර්මාණ ක්රමයෙහි අදුනු සහයෝගී සංස්ථාන භාවිතයෙන් ප්රභවත් අපේක්ෂාවක් හා ඉඩින්නේ ප්රභවත් ගුණාත්මක නිර්මාණයක් ලබා දෙන්නට, නිර්මාණ විශාලත්වය ප්රබල කිරීමට හා ආපත්තු ගුණාත්මකත්වය රැකියාවේදී මාර්කට් විරෝධයෙහි තාක්ෂණික උපායයක් රැකියාවේදී පවතින්නට. තාක්ෂණික ඇම්බිලිම සිතුවීමේ හැකියාව: දීර්ජ පාරිවාරික අනුප්රවේශය සහ ස්වීය නිර්මාණ සිතුවීමේ හැකියාවන් මත යෙදීමෙන්, එය අනුවාදීමෙන් තාක්ෂණික ඇම්බිලිම සිතුවීමේ කණ්ඩායමක් සහ හැකියාවක් ඇති. එය නව මාර්කට් අවශ්යතාවන්ට සාපේක්ෂව නිත්යම ප්රඵූති අනුකෘතිය සහ නිර්මාණ ක්රමයන් ප්රබල කළ හැකියාවක් ඇති.

පසු-වෙන්ත සහයෝගයේ පිළිබඳ ගුණාත්මකත්වය: පසු-වෙන්ත සහයෝගයට පැමිණීමට දෛශික ඉංජිනේරුවන්ගේ කණ්ඩායමක් ඇත, එය මුදල් භාවිතයෙන් ඇතිවන ගැටුම් ප්රශ්න මුදින්නට ලක්ෂ්යවාදී පිළිවෙලින් පිළිබඳව තාක්ෂණික සහයෝගය සහ විසඳුම් රැපුණිය යුතුය, මුදල් නිර්මාණයේ සාර්ථකත්වය තහනම් කර ගෙන මුදල් භාවිතයෙන් පාර්ශවයෙන් පිළිබඳ සුදුසුකම ඉඟිය යුතුය. මූලික තොරතුරු පැවැත්වීම: සමාචාර සහ බ්ලොග් බොළුවක් ඇතිවීමෙන්, එය පාර්ශවයෙන් තොරතුරු සහ සාමාන්ය ප්රශ්න බෙදීමට උපකාර කරයි, මූලික ප්රශ්න සහ විසඳුම් පිළිබඳව පාර්ශවයෙන් පිළිබඳ අවබෝධය හා මුදල් ගුණාත්මකත්වය අනුමාන කිරීමේ සාධක අනුමාන කිරීමේ අභිප්රාය ප්රදානය කරයි, මුදල් භාවිතයෙන් පාර්ශවයෙන් පිළිබඳ අවබෝධය සහ පාර්ශවයෙන් අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ අනුවාදීමේ

සියලු අධිකාර පරිභූත වේ. හාංග්ස් ඔේන් ඇඩ්ස්ට්රියුල් කො., සී. එක්සත් අධිකාර පරිභූත වේ